Steel framed polyethylene(PE) composite pipe

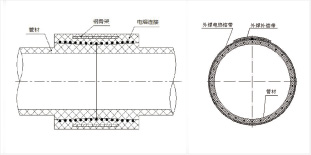

Steel framed polyethylene(PE) composite pipe uses high-strength copper coated steel with mesh structure as skeleton and high or medium density polythene as stuffing material, and its structure in production line though continuous and separately extruding and compound technique.

technical standard

The production and construction of products strictly implement international national standards.

Highly paid proprietary technology

Steel framed polyethylene(PE) composite pipe uses high-strength copper coated steel with mesh structure as skeleton and high or medium density polythene as stuffing material, and its structure in production line though continuous and separately extruding and compound technique.

industrial standard

The steel skeleton polyethylene plastic composite pipe has established a complete series of standards.

Ministry of construction standards

CJ/T 125-2014《燃气用钢骨架聚乙烯塑料复合管及管件》

HG/T 3690-2012《工业用钢骨架聚乙烯塑料复合管》

HG/T 3691-2012《工业用钢骨架聚乙烯塑料复合管件》

National Petroleum Chemical Industry Bureau

CJ/T123-2016《给水用钢骨架聚乙烯塑料复合管》

CJ/T124-2016《给水用钢骨架聚乙烯塑料复合管件

performance advantage

use the high quality PE materials

Creep resistance, excellent hydraulic performance, abrasion resistance ,corrosion resistance, sanitation and environmental-friendly, the service life can be over 50 years though.

Performance advantages

It is stable to composite steel and plastic for steel framed polyethylene plastic pipe, hardness with softness, creep resistance, impact resistance,rapid crack propagation resistance,lower coefficient of thermal expansion,good quality of Traceability,easy installation.

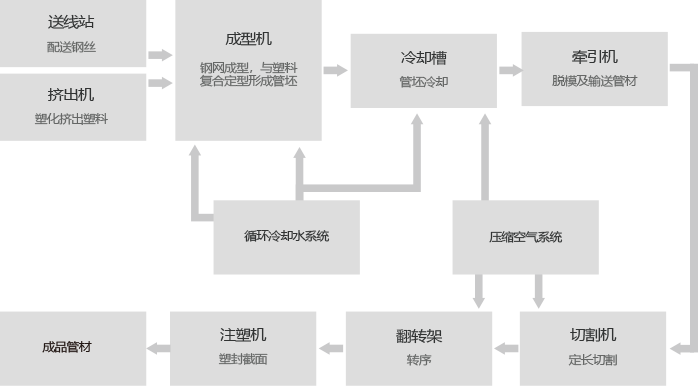

production technique

Steel skeleton of polyethylene plastic pipe USES continuous winding Angle welding net frame, plastic melt extrusion and frame synchronization composite molding process Which with high quality low carbon steel wire for enhanced phase, polyethylene (PE) as the matrix, through molding machine wire welding into the net, and the molten polyethylene composite extrusion in the compound nose, on the production line continuous composite molding, cooling traction incision sealing, get straight tube products

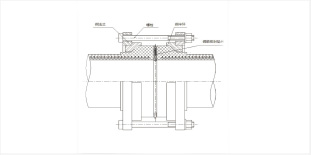

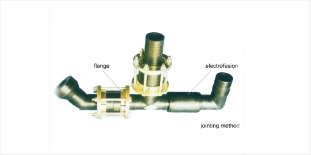

CONNECTION TYPE

hot melt connection

The steel framework polyethylene plastic composite pipe is used to absorb the mature connection technology and experience of traditional plastic and metal tube, and can be connected by electric fusion connection and live flange connection.

flanged joint

The steel framework polyethylene plastic composite pipe and other metal pure PE tube valves and gauges are connected by flange connection.

built-up connection

The connection of electric welding and flange connection of the composite pipe is higher than that of the pipe.

product standard

| Nominal internal classic (Dn) /mm |

Nominal pressure/Mpa | |||

|---|---|---|---|---|

| 1.0 | 1.6 | 2.5 | 4.0 | |

| Nominal wall thickness and limit deviation/mm | ||||

| 50 | — | — | √ | √ |

| 65 | — | — | √ | √ |

| 80 | — | — | √ | √ |

| 100 | — | √ | √ | — |

| 125 | — | √ | √ | — |

| 150 | √ | √ | — | — |

| 200 | √ | √ | — | — |

| 250 | √ | √ | — | — |

| 300 | √ | √ | — | — |

| 350 | √ | √ | — | — |

| 400 | √ | √ | — | — |

| 450 | √ | √ | — | — |

| 500 | √ | √ | — | — |

| 550 | √ | √ | — | — |

| 600 | √ | — | — | — |

Supporting pipe fittings

Nanchuan steel framework polyethylene plastic composite pipe fittings are complete, with all kinds of specifications of the elbow of three-way variable diameter electric fuse socket flange short pipe, can meet the complex conditions of the pipeline system supporting construction requirements.

Engineering Projects

Engineering Projects