HDPE winding structure-wall pipe

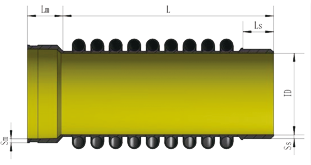

HDPE pipe with spirally enwound structured wall, an extra-large-diameter high-end buried water drainage pipe, is a new kind of safe and green pipe. It is a type of profiled structure-wall flexible tubing, which has a smooth inner wall, a spiral stiffening rib as its outer wall, and rib interface is manufactured via O-type spiral winding technology.

technical standard

The production and construction of products strictly implement international national standards.

ISO 21138-2007

《No pressure buried drainage structure wall pipe system.》

GB/T 19472-2004

《Embedded polyethylene (PE) wall pipe system.》

DIN 16961-1989

《The thermoplastics pipe in the outer wall and the inner surface of the smooth tube.》

BS EN 13476-2007

《Non - pressure underground drainage and drainage plastic piping system.》

performance advantage

Use the high quality PE materials

High Resistance to Corrosion, Resistance to Wearing, Excellent Hydraulic Performance, Green and Environment-friendly,The service life can be over 50 years though.

Performance Advantages

Strong Resistance to Impact, High Ring Stiffness above SN20, its seismic fortification intensity is as high as level 9, Convenient Connection, Good Sealing Performance Light Weight, Low Construction Cost

.png)

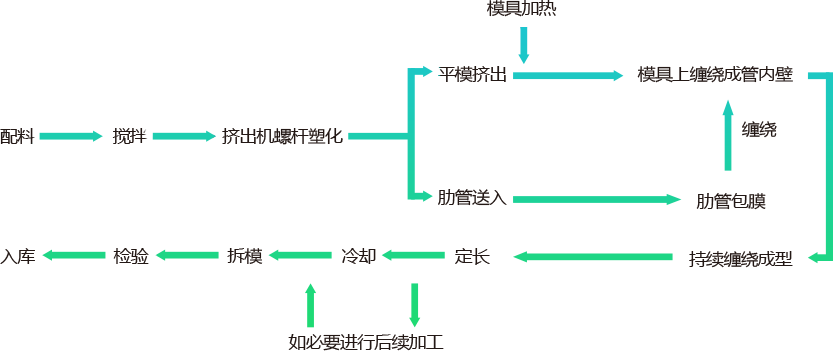

manufacturing technique

Material feeding、Mixing、Screw plasticizing of extruder、Mold heating、Flat die extrusion、Winding into the inner wall of tube on the mold、Winding、Ribbed pipe feeding、Ribbed pipe film coating、Continuous winding and forming、Length fixing、 Cooling、Form stripping、Inspecting、Warehousing、If it is necessary, subsequent processing is available

CONNECTION TYPE

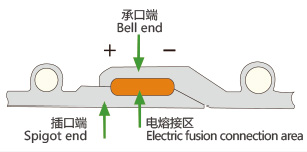

Socket type electrical connection

The thermal energy will melt the polyethylene material on the contact surface of the socket, and the PE molecules of the interface will solidify after the interpenetration and cooling of the PE molecular chains of the contact surface, so as to achieve the purpose of connection.

The characteristics of electrofusion connection at construction site.

The strength of the connection is better than the strength of the pipe, and the connection is simple and convenient.

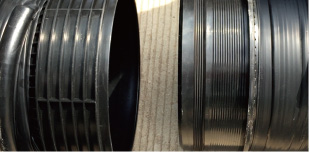

Throttling socket connection.

Nachan introduced patented technology to set up an independent annular ring on the socket or socket, and the mechanical occlusion socket was carried out, and the sealing ring was used, the double-layer seal was guaranteed, and the safe zero leakage was achieved. Convenient construction, without the use of third-party equipment; The adaptability of pipeline to construction conditions can be improved.

product standard

NOMINAL BORE DIAMETER DN(mm)

DN200、DN300、DN400、DN500、DN600、DN700、 DN800、DN900、DN1000、DN1100、DN1200、DN1300、DN1400、DN1500、DN1600、DN1700、DN1800、DN1900、DN2000、DN2200、DN2400、DN2500、DN2600、DN2800、DN3000、DN3500、DN4000

Ring Stiffness Class

Up to 20KN/m²,Customlzable,Thickness of earth-fill cover is up to 20m,

Supporting pipe fittings

Nachuan can also produce pipes that match the pipes, and realize the total plasticization of the pipe network.

All kinds of specifications HDPE material of the elbow tee pipe flange and special-shaped fittings.

Supporting facilities for inspection of shafts and other systems of concrete cast iron pipes and other non-metal pipes.

project case

advertising video